For a polished and professional look for your patios, garden paths, or other landscaping projects using Indian Sandstone paving, you must master cutting paving slabs. Especially if you are working around obstacles or want to create custom layouts, you must definitely know how to cut Indian Sandstone paving slabs.

Whether you are a homeowner tackling your paving project as a weekend job, a landscape designer, or a professional contractor, you can use this guide, each step to use tools and techniques for a precise and clean cut.

Why Proper Cutting Matters

Experts emphasize the importance of accurate cutting as the whole look of your outdoor space depends on it.

- Tight and Tidy Joints: If you properly cut your sandstone slabs, you ensure a seamless finish and avoid jagged breaks.

- Custom Fitting: Cutting your slabs is important for fitting around walls or complex edges like planting beds, gates, and water features.

- Durability: The cleaner and more accurate your cut is, the more you can avoid stress points that could lead to cracking in freeze-thaw cycles.

Not only does cutting matter, but laying your paving slabs accurately also plays a huge role in getting your whole outdoor space to look together. You can find the guide on laying sandstone paving slabs here: How to Lay Sandstone Paving Slabs

Required Tools

If you choose the right tools, you are already one step ahead in cutting sandstone slabs precisely.

- Wet or Tile Saw (For long and straight cuts)

- Circular Saw (Ideal for on-site work)

- Angle Grinder with Diamond Blades (For curved cuts)

- Block Splitter / Chisel and Hammer

- Marker, Square, and Tape Measure

- Safety Gear

Preparation for Cutting Sandstone

A professional prep is important as you can prevent material wastage, you get smooth edges to improve water drainage and aesthetic finishes, and also you get accurate cuts that simplify laying sandstone paving with straight joints.

- Selecting the Right Blade: Diamond blades are recommended for natural stones. A continuous rim ensures cleaner cuts.

- Safety: Use Ear and eye protection, gloves, and dust masks.

- Wet Cutting: For grinders or circular saws, wet the cutting line to reduce dust and cooling.

- Solid and Stable Base: Stabilise the slabs on an even and rigid surface like plywood or saw sawhorse.

- Mark Your Cuts: Use chalk or a pencil to mark before you cut.

Measuring and Marking

When it comes to how to cut a paving slab, follow the rule of thumb, “measure twice and cut once,” for your paving project.

- Plan the desired layout by placing your slabs on the visualised spacing.

- Measure precisely and also account for the joint spacing of 5mm to 10mm.

- Use a straight edge by snapping chalk lines for long cuts.

- Use adjustable-angle squares for precise cuts.

Methods of Cutting Sandstone Slabs

How do you cut sandstone slabs? There are a number of methods you can use when you ask how to cut Indian Sandstone. The best way to cut Indian sandstone slabs depends on the project you are tackling.

Wet Saw Cutting

This method is used for precise and straight cuts on large slabs.

- Align the slabs with your mark.

- Start cutting slowly and steadily. Do not push aggressively.

- Rinse the slab between cuts to clear debris.

Curricular Saw Technique

It is used for straight cuts when a wet saw is not available. It also works for smaller slab sizes.

- Use a diamond masonry blade.

- Cut shallow passes like 5 to 10mm depth before you start full-depth cuts.

- To maintain line accuracy, keep the straight edge guide

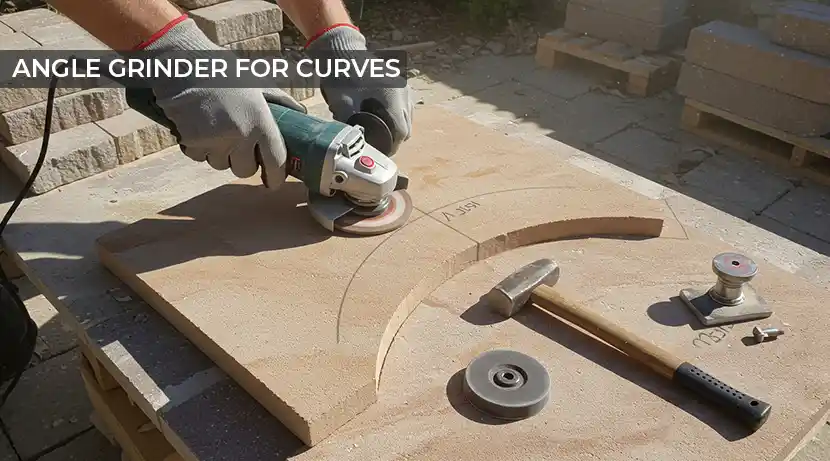

Angle Grinder for Curves

It is beneficial for curves, notches, and cutouts. In short, it is perfect for custom shapes in tiles or slabs.

- First, mark the curves clearly.

- Use a lighter granite blade.

- Make successive shallow cuts.

- Tap with a hammer and bolster if needed.

- Smooth the edges with a rubbing stone or a fine grinding disc.

Block Chisel and Hammer

If you are cutting paving slabs by hand, this method works best for rough straight cuts or breaking of edges. It is ideal for rustic finishes or thick stones.

- Score your slab edges on both sides.

- Tap your chisel gently along the score line.

Edge Finishing and Rubbing

When you cut your natural stones, the edges can be rough. Use edge finishing techniques like:

- Rubbing: Polish the sharp flares of the stone and chamfer edges.

- Angle Grinder: Light feathering for a softer cut finish.

- Sandpaper Pads: Progress from 80 to 120 grit to smooth the edges and blend in cuts.

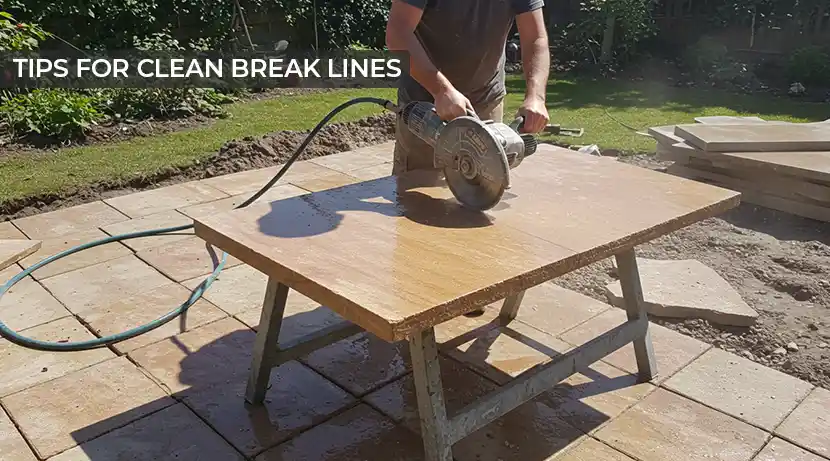

Tips for Clean Break Lines

If you would like to have clean break lines, follow the tips below:

- Ensure that your blade choice is correct and you go with a slow feed speed.

- Keep your cuts wet. If you are cutting large stone slabs outside, use a garden hose.

- Choose a stable platform and support the slab to prevent vibrations.

- Let the blades do their work. Do not force cuts as it can crack your slab.

Common Mistakes to Avoid

Avoid the following mistakes during paving stone cutting, in order to have a clean outdoor space you can enjoy for years without worrying.

- Putting too much pressure can cause chipping or irregular edges.

- Using incorrect blade types that can chip your stone. The blades must have a continuous rim.

- Cutting sandstone slabs dry is a no-no, as it generates excessive dust and heats the blade.

- Skipping safety can be life-threatening. Eye, ear, and lung protection is non-negotiable.

Working with Angled Cuts and Corners

It is complicated to cut paving slabs for the angled edges or corners. Do this for precise cuts, especially if you are laying Sandstone slabs like Kandla Grey or Raj Green and want to avoid expensive mistakes:

- Template the odd shapes with cardboard first.

- Snap chalk lines along the inside cuts.

- Start with shallow passes before you make deep cuts.

- Use an angle grinder or block splitter to finish corners accurately.

Post-Cutting Maintenance

After you cut your slabs, do this:

- Let your slabs dry fully before sealing them.

- Clean all the dust and grit before laying them in the decided layout.

- Smooth the edges with rubbing stones.

- Seal the sandstone pavement within 2 to 4 weeks to protect it from permanent staining and weathering.

Eco-Friendly Disposal

After cutting the sandstone paving, you need to take care of the pieces left behind.

- Collect the stone cut-offs for garden use.

- Recycle the unused pieces when available.

- Sweep your area thoroughly in order to avoid onsite hazards and accidents.

Final Thoughts

Cutting Indian Sandstone paving accurately ensures that you get a professionally done result, like detailing, fit, and long-term durability. If you choose the right blades, tools, techniques, and safety precautions, you surely can achieve clean cuts, even for complex spaces.

If you are ready to buy Indian Sandstone paving slabs or want detailed laying advice, Royale Stones, your trusted UK paving supplier, is always here to support all your outdoor projects. Browse our wide range of Indian Sandstone slabs and build your next patio with us!

Frequently Asked Questions

Q: Is Indian sandstone easy to cut?

A: Yes, if you have the proper tools for large paving slab cutting, complex edges, and smaller sandstone sizes. Sandstone is a natural stone that is softer than some other natural stones, such as granite, but harder than limestone.

Q: What is the best blade for cutting Indian sandstone?

A: A diamond continuous-rim masonry blade is the best blade for cutting sandstone. Either a wet saw or a circular saw-rated, you need to make sure that your blade is sharp, has around 115 to 125mm diameter, and has an 8 to 10mm kerf.

Q: What is the easiest way to cut sandstone?

A: By using a wet saw, you get precise and clean cuts. For onsite adjustments, use a circular saw with a straight-edge guide.

Q: How to cut Indian Sandstone with a circular saw?

A: Use a circular saw for cutting paving slabs by fitting a diamond masonry blade. Mark the area that needs to be cut, secure the slab, make a shallow guide pass first, and then follow with full-depth cuts. Make sure your blades are wet at all times.

Q: How to cut Indian sandstone with a grinder?

A: An angle grinder with circular diamond blades is one of the most efficient ways to cut Indian Sandstone. For cutting Indian sandstone with an angle grinder, mark your lines, take multiple slow passes, finish corners gradually, and smooth the edges using rubbing stones.

Q: How to cut Indian sandstone slabs by hand?

A: Cutting Indian sandstone by hand using a chisel and hammer. First, score the surface along the marked lines using a chisel and gentle hammer taps. Once the score is deep enough, strike the chisel firmly to split the slab along the line. This method works best for straight cuts.